Drilling Engineering Tutorials

Drilling Tutorials 2011

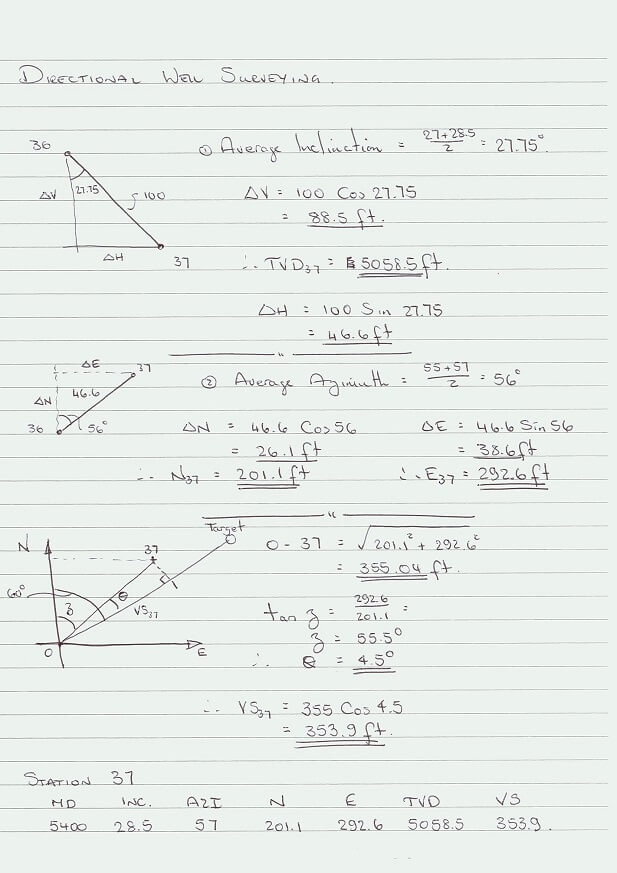

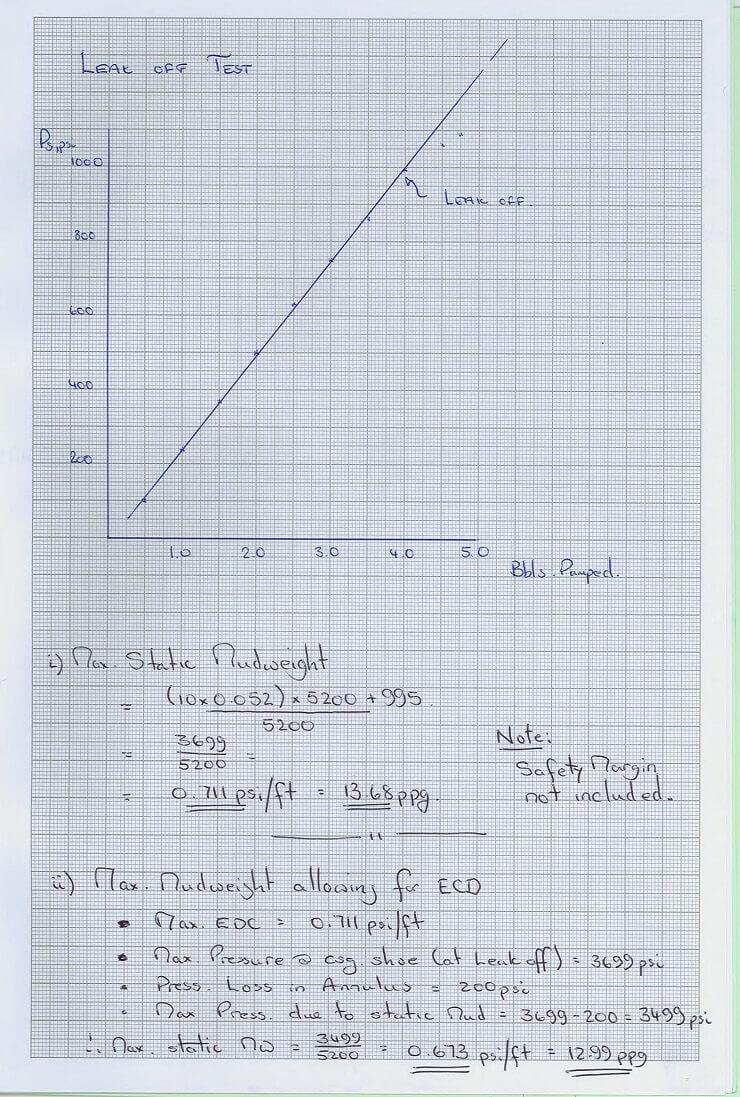

Ex. 1 Leakoff Test

After having conducted a Leak off test at the 13 3/8" casing shoe of a vertical well the following data is reported :

TVD of 13 3/8" Shoe : 5200 ft. Mudweight in hole : 10.0 ppg

|

Vol. pumped bbls |

Surface Pressure psi |

|

0.5 |

100 |

|

1.0 |

240 |

|

1.5 |

370 |

|

2.0 |

500 |

|

2.5 |

630 |

|

3.0 |

750 |

|

3.5 |

860 |

|

4.0 |

995 |

|

4.5 |

1060 |

|

4.75 |

1090 |

- What is the maximum allowable static mudweight in the next (12 1/4") hole section?

- Assuming that the circulating pressure losses in the annulus will be 200psi, what is the maximum allowable mudweight, (allowing for ECD) in the next (12 1/4") hole section?

- What would be the MAASP in the next hole section, if the mudweight in the next hole section was increased to 11.0 ppg ?

(State clearly any assumptions in your answer) (6)

Drilling Tutorials 2011

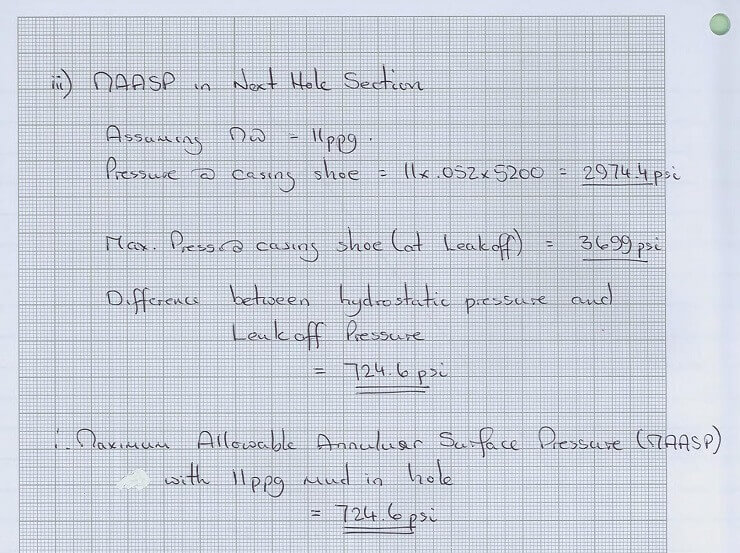

Ex. 2 Well Control

Whilst drilling the 12 1/4" hole section of a vertical well with a mudweight of 10.5 ppg the driller detects a kick. The well is shut in and the following information is gathered

Surface Readings :

Shut in Drillpipe Pressure : 700 psi Shut in Annulus Pressure : 900 psi Pit Gain : 33 bbls

Hole / Drillstring Data :

Hole Size : 12 1/4 "

Depth of kick : 7250 ft. TVD Previous Casing Shoe : 13 3/8", 53.5 lb/ft Depth 13 3/8" shoe : 3800 ft. TVD

LOT at Previous shoe : 3230 psi (0.85 psi/ft Equivalent Mudweight)

BHA : Bit : 12 1/4"

Drillcollars : 400 ft of 9" x 2 13/16"

Drillpipe : 5", 19.5 lb/ft

- Calculate and discuss the following :

- The type of fluid that has entered the wellbore ?

- The mudweight required to kill the

(8)

VOLUMETRIC CAPACITIES

|

Drillpipe |

bbls/ft |

ft3/ft |

|

5" drillpipe : |

0.01776 |

0.0997 |

|

Casing 13 3/8" 72 lb/ft Casing: |

0.1480 |

0.8314 |

|

Open Hole 13" Hole |

0.1642 |

0.9220 |

|

18" Hole |

0.3147 |

1.7671 |

|

Annular Spaces | ||

|

12 ¼" hole x 5" drillpipe |

0.1215 |

0.6822 |

|

12 ¼" hole x 9" drillcollars: |

0.0671 |

0.3767 |

|

13” Hole x 9 5/8" Casing |

0.0742 |

0.4166 |

|

18" hole x 13 3/8" Casing: |

0.1410 |

0.7914 |

|

20" Casing x 13 3/8" Casing: |

0.1815 |

1.0194 |

|

8 1/2" hole x 5" drillpipe: |

0.0459 |

0.2577 |

|

8 1/2" hole x 6 1/4" drillcollars: |

0.0330 |

0.1926 |

Drilling Tutorials 2011

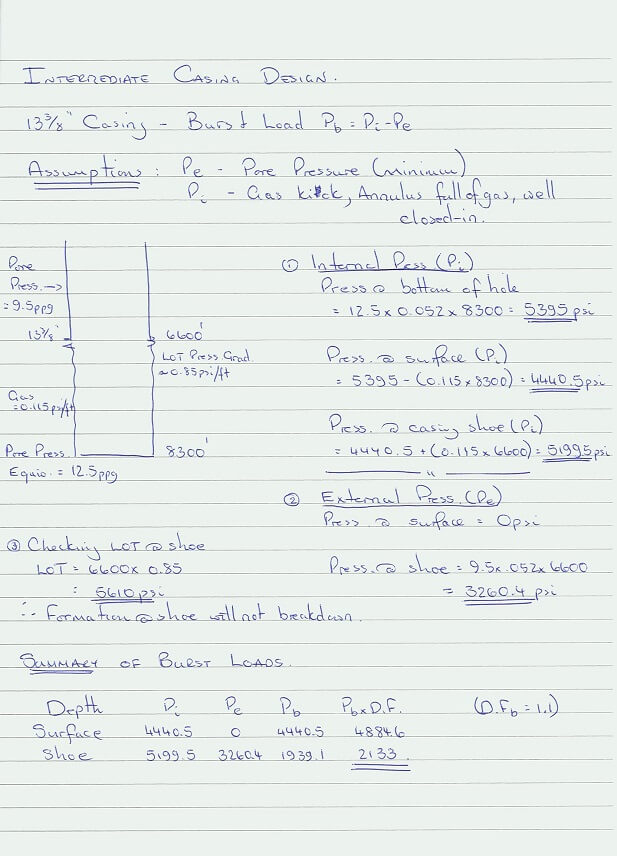

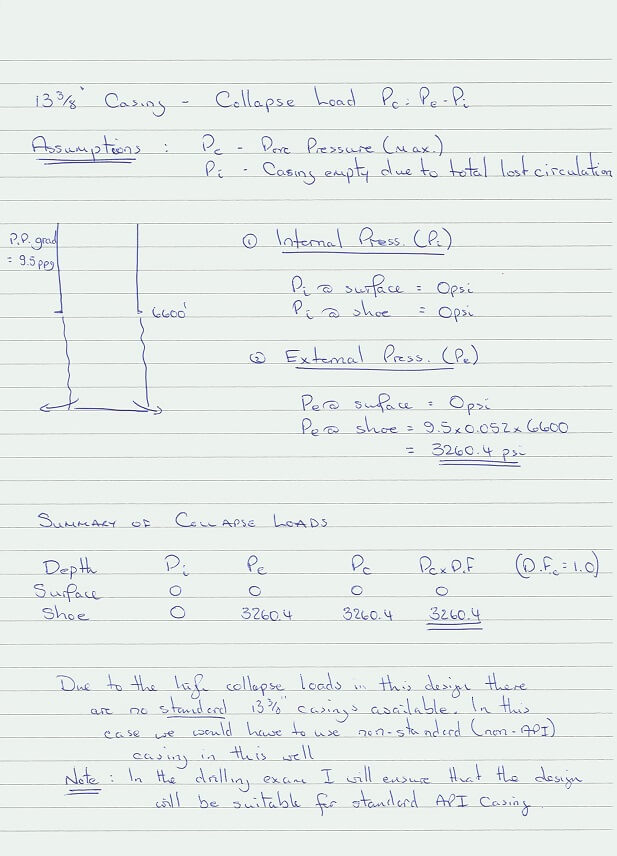

Ex. 3 Intermediate Casing Design

You are required to calculate the burst and collapse loads on the 13 3/8” intermediate casing for a gas development well on the basis of the following data :

|

Casing Size : Setting Depth : Formation Fluid Density : |

13 3/8" 6600 ft 9.5 ppg | |

|

Mud weight in which the casing is to be run : Depth of next (12 1/4”) hole section : Expected Pore Pressure Gradient at |

11.5 ppg 8300 ft | |

|

bottom of 12 1/4” hole: |

12.5 ppg | |

|

Expected Frac. Pressure Gradient at the 13 3/8” shoe Expected gas gradient : |

0.85 psi/ft. 0.115 psi/ft | |

|

Design Factors : (Burst) |

1.1 | |

|

(Collapse) |

1.0 |

Drilling Tutorials 2011

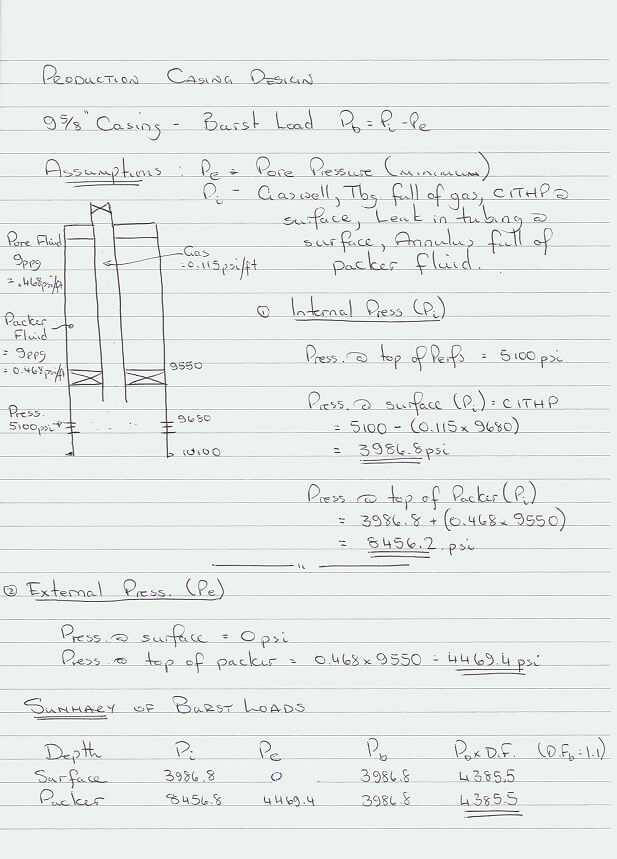

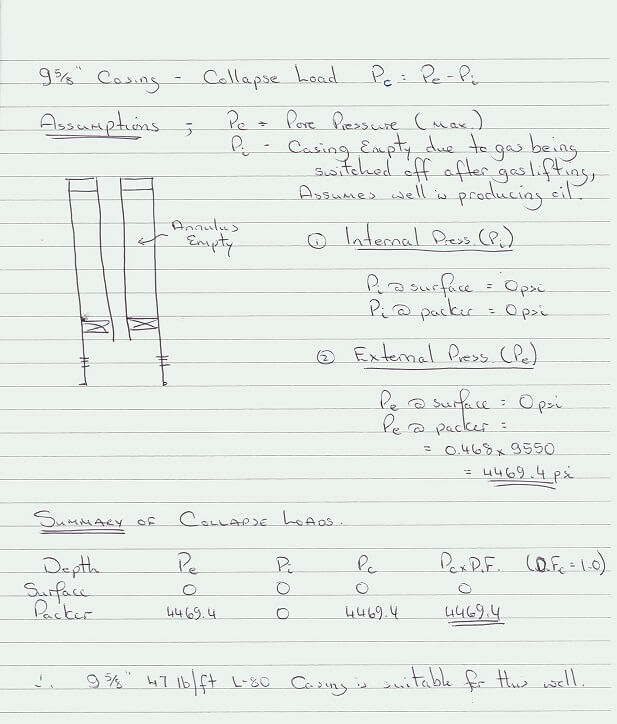

Ex. 4 Production Casing Design

You are required to calculate the burst and collapse loads on the 9 5/8" production casing string for a gas development well on the basis of the following data :

|

Setting Depth of 9 5/8" Casing : Top of Production Packer : Formation Fluid Density : Expected gas gradient : |

10100 ft 9550 ft 9 ppg 0.115 psi/ft |

|

Depth of Production Interval (TVD) : |

9680 - 9950 ft |

|

Maximum expected pressure at top of Perforations : |

5100 psi |

|

Packer fluid density : |

9 ppg |

|

Design Factors (burst) : |

1.1 |

|

(Collapse) : |

1.0 |

Drilling Tutorials 2006

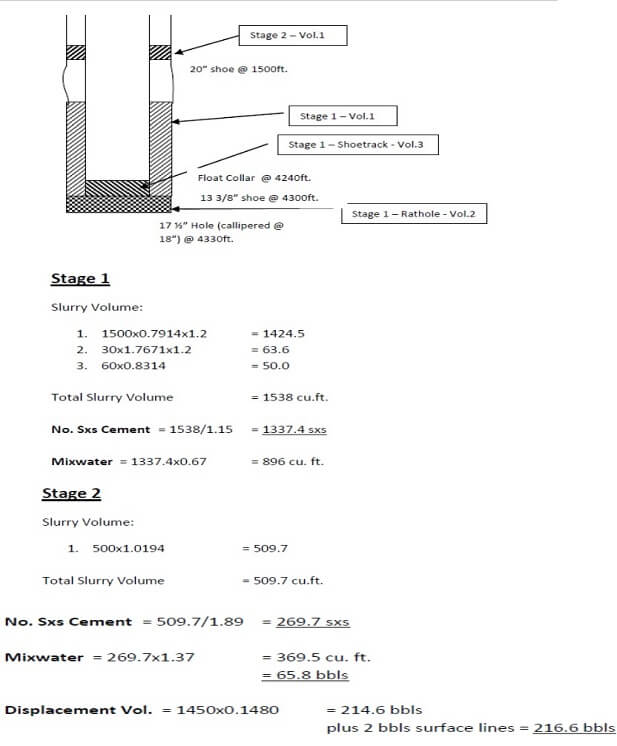

Ex.6 - Cementing

The 13 3/8” intermediate casing string of a well is to be cemented in place with a two stage cement job. The details of the job are as follows :

|

Previous Casing Shoe (20") : |

1500 ft. |

|

13 3/8" 72 lb/ft Casing Setting Depth : |

4300 ft. |

|

17 1/2" open hole Depth (Calipered @ 18" average) : |

4330 ft. |

|

Multi-Stage Collar Depth : |

1450 ft. |

|

Shoetrack : |

60 ft. |

|

Mud Density When cement job starts : |

12 ppg |

Cement stage 1 (4300-2800 ft.)

Class 'G' + 0.2% D13R (retarder) : 15.8 ppg

Yield of Class 'G' + 0.2% D13R : 1.15 ft3/sk

Mixwater Requirements : 0.67 ft3/sk

Cement stage 2 (1450-950 ft.)

Class 'G' + 8% bentonite + 0.1% D13R : 13.2 ppg Yield of Class 'G' + 8% bentonite + 0.1% D13R : 1.89 ft3/sk Mixwater Requirements : 1.37 ft3/sk

- Calculate the following (See Attachment 1 for capacities):

- The required number of sacks of cement for the 1st stage and 2nd stage of the job (Allow 20% excess above calliper in openhole).

- The volume of mixwater required for each

- The displacement volume for each

(12)

VOLUMETRIC CAPACITIES

|

Drillpipe |

bbls/ft |

ft3/ft |

|

5" drillpipe : |

0.01776 |

0.0997 |

|

Casing 13 3/8" 72 lb/ft Casing: |

0.1480 |

0.8314 |

|

Open Hole 13" Hole |

0.1642 |

0.9220 |

|

18" Hole |

0.3147 |

1.7671 |

|

Annular Spaces | ||

|

12 ¼" hole x 5" drillpipe |

0.1215 |

0.6822 |

|

12 ¼" hole x 9" drillcollars: |

0.0671 |

0.3767 |

|

13” Hole x 9 5/8" Casing |

0.0742 |

0.4166 |

|

18" hole x 13 3/8" Casing: |

0.1410 |

0.7914 |

|

20" Casing x 13 3/8" Casing: |

0.1815 |

1.0194 |

|

8 1/2" hole x 5" drillpipe: |

0.0459 |

0.2577 |

|

8 1/2" hole x 6 1/4" drillcollars: |

0.0330 |

0.1926 |

Solution - Cementing Tutorial

Drilling Tutorials 2011

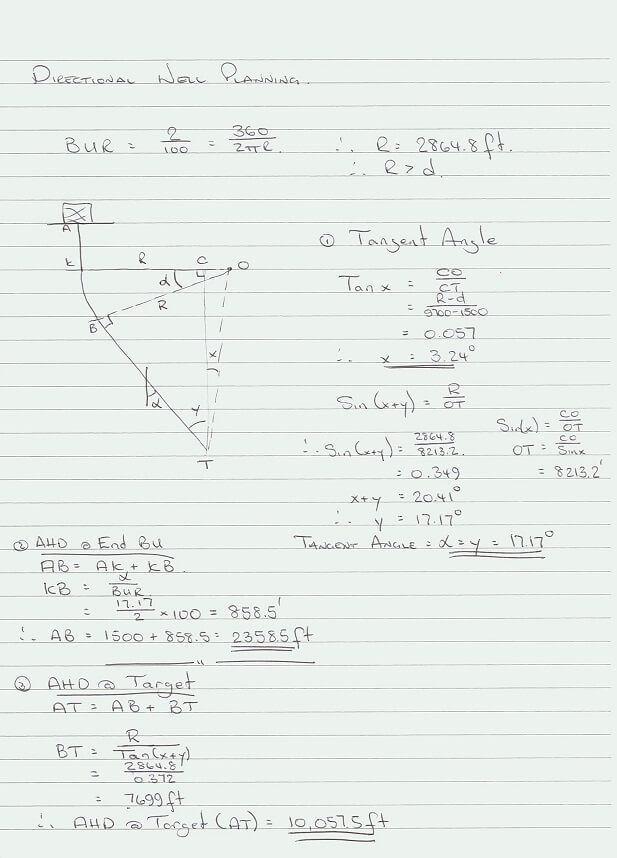

Ex. 5 Directional Well Planning

Using the following data, design a deviated well using a build and hold trajectory.

TVD Target 9700 ft

Horizontal Departure of Target 2400 ft

KOP 1500 ft

BUR 2 degrees/100 ft

Determine the following :

- Tangent

- Along Hole Depth at the end of the Build up Section

- True Vertical Depth and Horizontal departure of End Build up Section

- Along Hole Depth at

Drilling Tutorials 2011

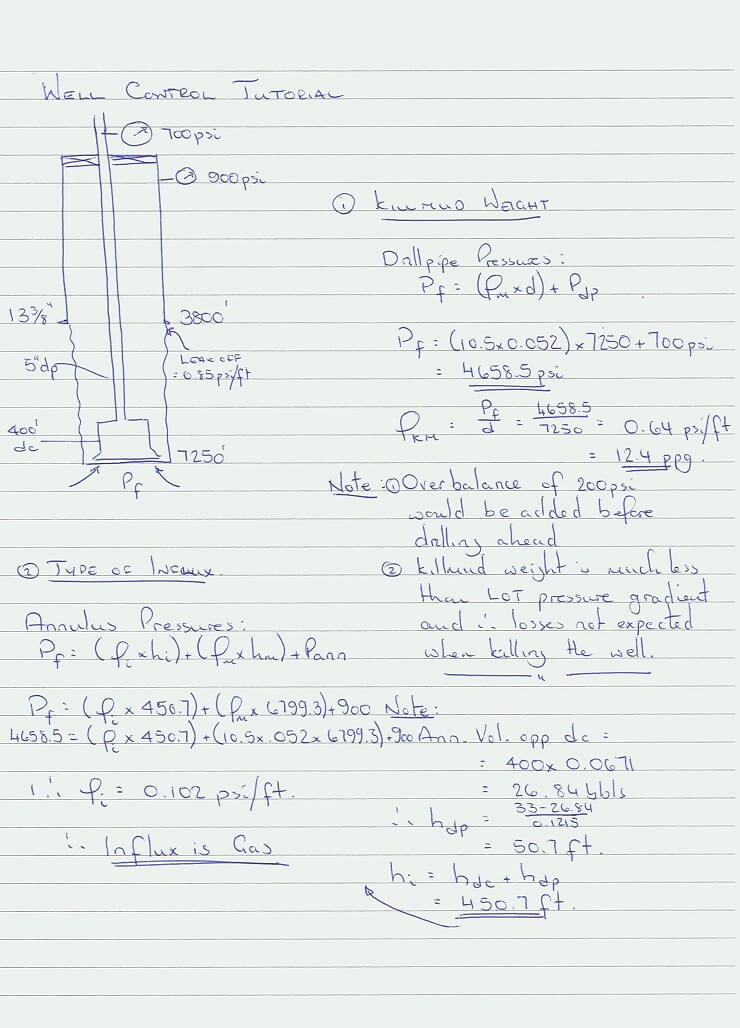

Ex. 6 - Directional Surveying

Whilst drilling a deviated well to a target at 9800 ft. TVD. The following data is recorded at station No. 37 (The target bearing is 60o)

|

STATION |

MD |

INC. |

AZI. |

N |

E |

TVD |

VS |

|

36 |

5300 |

27 |

55 |

175 |

254 |

4970 |

306 |

|

37 |

5400 |

28.5 |

57 |

Calculate the North and East co-ordinates, TVD and vertical section of station No. 37 using the average angle method.